When it comes to handling materials, using the right equipment can make a huge difference between efficiency and disaster. Vertical lifts are economical and versatile. In addition, they offer a unique range of features over similar tools.

If you are active in the material handling market, learn about the benefits of scissor lifts and why you should consider using them.

Simply put, scissor elevators use a cross-crossing foundation that can be extended over a platform to lift people. They are a sub-type of aerial work platform and can be used by a single operator. These elevators come in a variety of sizes and shapes, but all have the same benefits.

While you can use other tools to achieve the same effect, scissor lifts have certain benefits, as we'll see below.

Since some elevators can reach heights of up to 32 feet, this is a tool that allows your workers to reach places that would otherwise be difficult to reach.

Obviously, height and carrying capacity are closely related to total weight. So, the heavier you lift it, the higher it can reach and the more weight it can carry.

These elevators are exceptionally easy to operate. The controls are simple and literally dumb, which reduces operator fatigue. This also means that operators can be trained in the use of the tool in a matter of days, so you can use the tool with minimal downtime.

Scissor lifts are basically the most compact working platform you can find. This is important for tight Spaces, such as living Spaces or compact warehouses where stacked crates limit height.

Scissor lifts are one of the most compact lifting devices available on other high-altitude platforms, which require a lot of ground space to operate. The total area required is almost equal to the area of a liftable platform, making these lifts easy to store.

Depending on your business, you may need to customize your elevator to meet your business needs. Scissor lifts are customizable. For example, you can install tilting devices on your phone to minimize the risk of operator falls. Or you can attach a turntable to it so that it can rotate and lift the platform.

Scissors are arguably the most economical and versatile solution compared to all the other options. You can service the whole warehouse with one vertical lift. In addition, hydraulic lifts consume almost no power, adding more efficiency.

However, it is important to remember that scissor lifts are not suitable for all industries. Some people argue that scissor lifts pose a safety risk and that they are simply not suitable for certain types of work.

If scissor lifting isn't for you, another vertical lift is a great option. Dig-dog provides custom lift solutions for vertical lifts. We are experts in vertical lifting, a well-known brand in the vertical reciprocating conveyor industry. All of our lift platforms are designed with a range of safety features and are rigorously tested before reaching your lift platform.

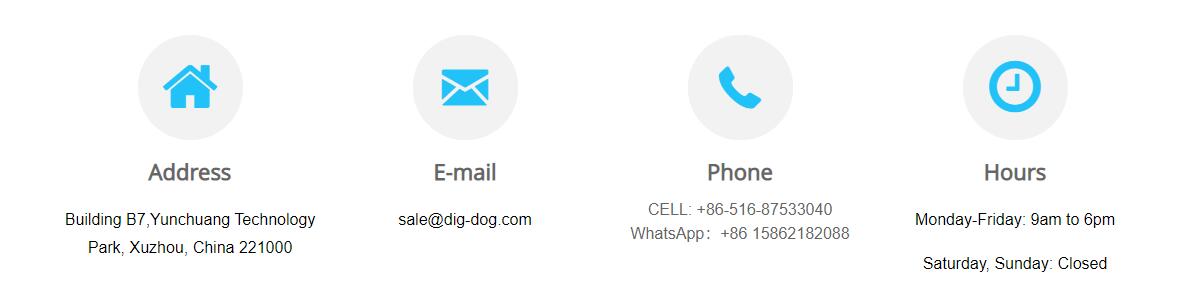

Contact us today to find the right lift platform for your company!

A Ultimate Guide to Clamp Forklifts and Attachments

A Ultimate Guide to Clamp Forklifts and Attachments

How To Choose The Right Compact Wheel Loader

How To Choose The Right Compact Wheel Loader

How Much Does a Forklift Weigh?

How Much Does a Forklift Weigh?

How Much Does a Backhoe Weigh

How Much Does a Backhoe Weigh