This is a beginner's guide to the basic structure and functions of an excavator. In this blog post you will learn about:

Chapter 1: Basic components of excavator

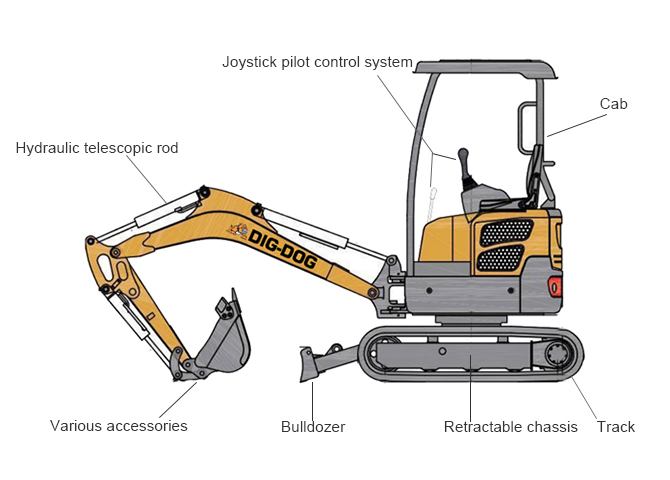

The structure of the excavator includes power unit, working device, slewing mechanism, control mechanism, transmission mechanism, traveling mechanism and auxiliary facilities.

From the appearance, the excavator consists of three parts: working device, upper turntable, and traveling mechanism. Among them, the working device is a device that directly completes the excavation task. It is composed of three hinged parts: boom, stick and bucket. The lifting and lowering of the boom, telescopic stick and bucket rotation are all controlled by reciprocating double-acting hydraulic cylinders. The upper turntable is the operating platform of the excavator, which is equipped with components such as the engine, control panel, and instrument panel. The traveling mechanism includes crawler tracks, walking frames and other parts, allowing the excavator to move on different terrains.

In addition, depending on the structure and purpose, there are many types of excavators, such as crawler, tire, walking, fully hydraulic, semi-hydraulic, full rotation, non-full rotation, general type, special type, articulated type, telescopic arm Formula etc.

Chapter 2: What can we do with a hydraulic crawler excavator?

Hydraulic crawler excavator is a powerful piece of construction machinery and equipment with many uses, including but not limited to the following:

Excavation operations: Hydraulic crawler excavators are equipped with powerful buckets that can excavate various types of soil and rocks. They are widely used in earth excavation, foundation excavation, road cutting construction and other fields.

Loading and transportation: Hydraulic crawler excavators can load excavated materials into transport vehicles, or unload them directly to designated locations, such as stockpiles, landfills, etc.

Leveling operations: Hydraulic crawler excavators can use their bulldozers and scrapers to perform ground leveling, backfilling and other operations to improve operating efficiency and accuracy.

Crushing operations: Hydraulic crawler excavators can be equipped with breakers and other devices to perform rock crushing, concrete crushing and other operations, and are widely used in construction demolition, road maintenance and other fields.

Hoisting operations: Hydraulic crawler excavators can be equipped with hoisting equipment, such as hooks, grab buckets, etc., to perform hoisting, transportation and other operations. They are widely used in construction sites, logistics and transportation and other fields.

Other operations: Hydraulic crawler excavators can also be used in river dredging, fire rescue, military engineering and other fields. Its versatility and flexibility make it one of the indispensable and important equipment in the engineering field.

In general, a hydraulic crawler excavator is a versatile engineering machinery equipment with multiple uses such as excavation, loading, transportation, leveling, crushing, and hoisting, and is suitable for various working environments and fields.

Chapter 3: Excavator parts and their functions

The components of a hydraulic crawler excavator and their functions are as follows:

Working device: This is a device that directly completes the excavation task. It is composed of three parts: boom, bucket, and bucket. The lifting and lowering of the boom, telescopic arm and bucket rotation are all controlled by reciprocating double-acting hydraulic cylinders. In order to meet the needs of various construction operations, hydraulic excavators can be equipped with a variety of working devices, such as excavation, lifting, loading, leveling, clamping, bulldozing, impact hammers and other working tools.

Slewing device: This is the body of the hydraulic excavator. The upper part of the turntable is equipped with a power device and a transmission system.

Traveling device: including crawlers, walking frames and other parts, allowing the excavator to move on different terrains.

Power unit: generates power and transmits it to the hydraulic system or other working devices, mainly composed of engines.

Hydraulic system: It consists of hydraulic pumps, control valves, hydraulic cylinders, hydraulic motors, pipelines, fuel tanks, etc., and is used to transmit and control power.

Electrical control system: including monitoring panel, engine control system, pump control system, various sensors, solenoid valves, etc., used to control various actions and operations of the excavator.

In addition, some auxiliary equipment may be equipped according to actual needs. For more information, it is recommended to consult a professional technician.

Chapter 4: What is the most important part of an excavator?

The most important components of an excavator are the engine and hydraulic system.

The engine is the power source of the excavator, providing the excavator with the required power and torque to enable it to work properly. At the same time, the quality and performance of the engine will also directly affect the overall performance and efficiency of the excavator.

The hydraulic system is the key component that controls the movement of the excavator, including hydraulic pumps, hydraulic cylinders, hydraulic motors, valves, etc. The hydraulic system can convert the power of the engine into mechanical energy to drive the working device of the excavator to perform excavation, rotation, lifting and other actions. The quality and performance of the hydraulic system will also directly affect the overall performance and efficiency of the excavator.

Therefore, choosing a high-quality engine and hydraulic system is very important when purchasing an excavator.

When you need to purchase, use and maintain a hydraulic crawler excavator, don't forget to consult DIG-DOG Construction Machinery. We specialize in providing a variety of high-quality excavator products and services to help you solve various engineering problems and improve work efficiency. Please feel free to contact us and we will be happy to serve you.

Unveiling the Top 10 Must-Have Construction Vehicles for Your Business

Unveiling the Top 10 Must-Have Construction Vehicles for Your Business

How High Lift Skid Steers Save You Time and Money

How High Lift Skid Steers Save You Time and Money

Attachments Turn Mini-excavators Into Multipurpose Machines

Attachments Turn Mini-excavators Into Multipurpose Machines

BONOVO Group at INTERMAT 2024 Paris Exhibiton

BONOVO Group at INTERMAT 2024 Paris Exhibiton